Advanced CNC Machining, Milling & Turning

By utilising the open architecture and complete networking potential of Okuma machinery, our CNC production capabilities offer both extremely high quality and large quantities. The precision offered by CNC machines is unparalleled, allowing for a huge amount of configurations and product possibilities. From developing the customer’s original idea, to building the CAD drawing, to proof of concept and the final production… SQP are the CNC specialists.

Schedule Your MeetingOur CNC Machines

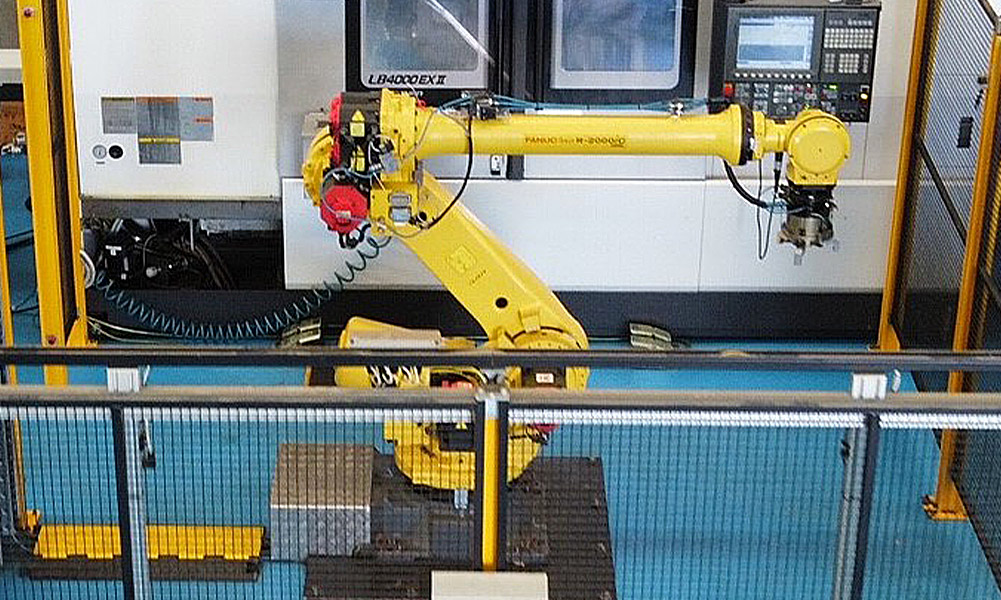

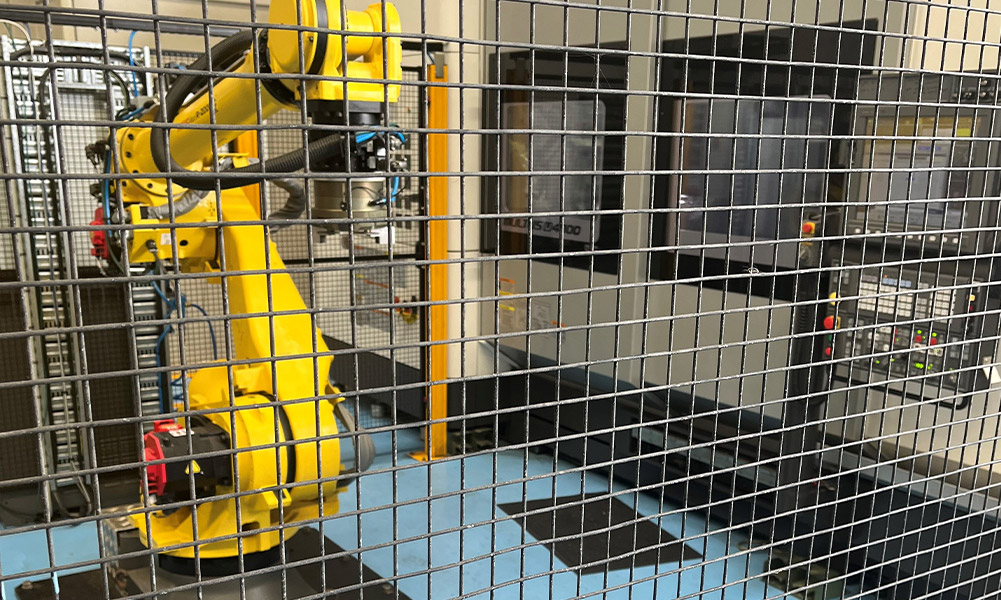

Our workshop is a powerful ensemble of Okuma machines, including three LB3000EX horizontal lathes, an Okuma LB4000 with robot, an Okuma LB400 horizontal lathe, an Okuma Multus U4000 with robot, an Okuma Millac 761 5-Axis machining centre and a Okuma MB56-VA 5-Axis machine, providing consistent high quality at any volume.

Okuma LB3000 (x3 Machines)

- Max turn diameter 410mm

- Max swing diameter 580mm

- Z-Axis1000mm

- 81mm Spindle bore

- With live tooling and bar feeders

- Max dia 80mm

- Max length 1800mm

- Attachments

- Bar feeders (80mm dia * 1800 length)

- Parts Sorter

Okuma LB4000 with Robot

- Max Work Length: 380, 750, 1500, 2150mm

- Max Turning Dia: 430-480mm

- Spindle Speed (min-1): 4200, 3000

- Spindle Bore: 91, 112mm

- Turret: V12

- Motor (VAC) (kW): 30/22, 37/30

- Floor Space: 3,050/4,725×1,900mm

- Spec: L/M/MY

- L Turning only

- M Multitasking specs (M-tool)

Okuma LB400

- Chuck Size: 254 mm

- Power: 22.4 kW

- Max RPM: 38 RPM

- Turning Dia: 419.1 mm

- Swing: 619.76 mm

- Machining Length: 647.7 mm

- Control: CNC (OSP E100L)

Okuma Multus U4000 with Robot

- Max Turning Diameter: 650mm

- Spindle Nose Type: JIS A2-8 [JIS A2-11]

- Speed Range (min⁻¹): 45~4,200

- Standard Power (20 min/cont): 22/15 kW

- Rapid Traverse Xa/Za (m/min): 50

- Rapid Traverse Zb/Y (m/min): 40

- Rapid Traverse Xb (m/min): 25

Okuma Millac 761 5-Axis

- Table Dimensions: 1,800 x 720mm

- Travel X/Y/Z: 1,540 x 760 x 660mm

- Max Load (kg): 2,000

- Rapid Traverse (X-Y-Z) (m/min): 16

- Spindle Speed (min⁻¹): 20~4,000 [30~6,000; 50~12,000; 50~15,000]

- Spindle Power (kW): 18.5/15 [26/18.5]

Okuma MB56-VA 5-Axis

- Max Machining Volume: 1,050 x 560 x 460mm

- Table Size: 1,300 x 560mm

- Spindle Speed (min⁻¹):50~8,000, [50~15,000, 50~20,000, 50~25,000, 50~35,000]

- Spindle Motor Power – Low Range (kW): 11/7.5 [22/18.5, 30/22, 15/11, 15]

- Rapid Traverse (m/min): X-Y: 40 Z: 32

- Magazine Capacity: 20 [32, 48]

Materials we use

We work very closely with our suppliers; utilising their expertise on materials and gaining maximum price advantage. We listen and learn from their insider knowledge, which we pass on to our customers. In fact, it’s always worth having a discussion about materials before a project, as there are often material solutions customers may not be aware of.

We machine pretty much every material, from plastics and synthetics, to steel, aluminium and bronze. In some cases, where rare or hard-to-find materials are not stocked in WA, we stock supplies ourself – saving our customers both time and money.

Here are some examples of the materials we use:

Plastics

- Acetal

- HDPE

- UHMWPE

- Techtronic

- Peek

Stainless Steel

- 304, 316, 431, 630

- Super Duplex

- 2205, 2507

- Titanium Inconell 625, 718

Steel

- 1020,1030,1045

- NACE Compliant 4140

- EN36

Bronze

- LG2, PB1

- AB1,2

- Brassc

Work with us in 4 easy steps

![]()

Upload Your Design For Quotation

![]()

Send A Purchase Order

![]()

Start Manufacturing

![]()